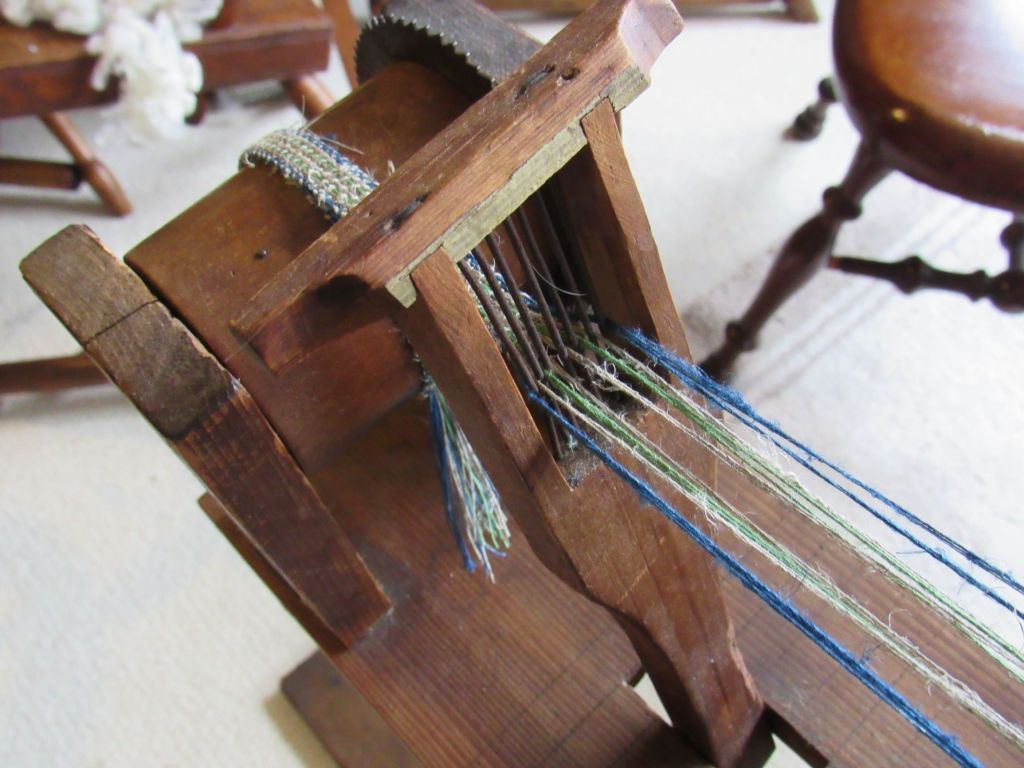

Of all the pieces in my collection, this little loom may be the one I treasure the most. In part, because it is a particularly colorful and complete example of a rare loom, but also because of the sheer pleasure of weaving on it.

This style loom, designed for weaving bands (also called ribbons and tapes), generally is referred to as a “Leksand loom,” because it was made only in the Leksand area of Sweden. Its design is unique.

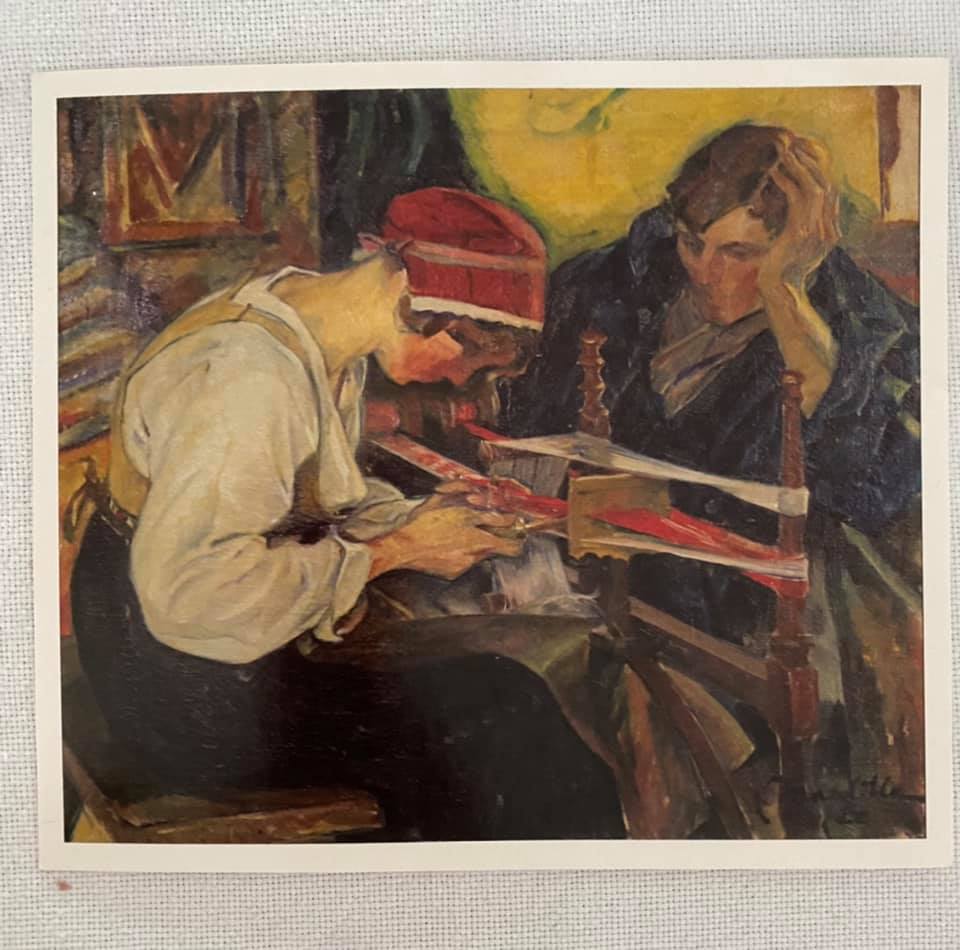

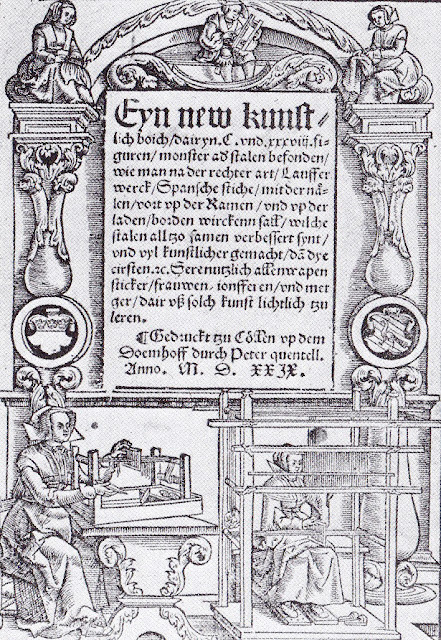

To start with, the weaver works from the side of the warp. While this horizontal style is unusual these days, it must have been quite common in the 15th century.

Medieval manuscripts show many varieties of sideways-style band looms,

some with tablets,

some with floating rigid heddles,

and, at least one, with what we now call an inkle-style set up (“inkle” is believed to be a corruption of the 16th century English word “linckle,” meaning “band” or “tape”).

While horizontal band looms were used in several parishes in Sweden,

only in Leksand did looms have the added feature of a small wooden rigid heddle attached to a foot treadle.

With this ingenious design, the pattern threads run through the holes in the rigid heddle.

One set of background threads runs through the heddle slots and the other set runs over a corrugated rod and through half-heddles.

It functions similarly to a double-slotted (Sunna or pattern) heddle in backstrap weaving. Using the foot treadle, the pattern threads can be raised together, all in one plane, separate from the background threads.

Elevating and isolating the pattern threads this way allows the weaver to easily pick out the band patterns with a band knife.

It is a brilliant innovation for fast, efficient weaving of complicated band patterns.

And the prolific Leksand weavers took advantage of these little looms to produce stunning bands in great quantities. Most often red and white or black and white, the Leksand bands were woven with a seemingly never-ending variety of patterns, some dating back to the thirteenth century. Foulkes, p. 16. The bands were used for hats, belts, straps, ties, laces, and decorative edging.

In Sweden, Kirsi Manni is a rich source of information about Leksand looms and bands, including invaluable knowledge learned from local older weavers.

Kirsi kindly welcomed me to her home in Sweden last summer where she collects spinning wheels, textile tools, and these rare looms to preserve them for future generations.

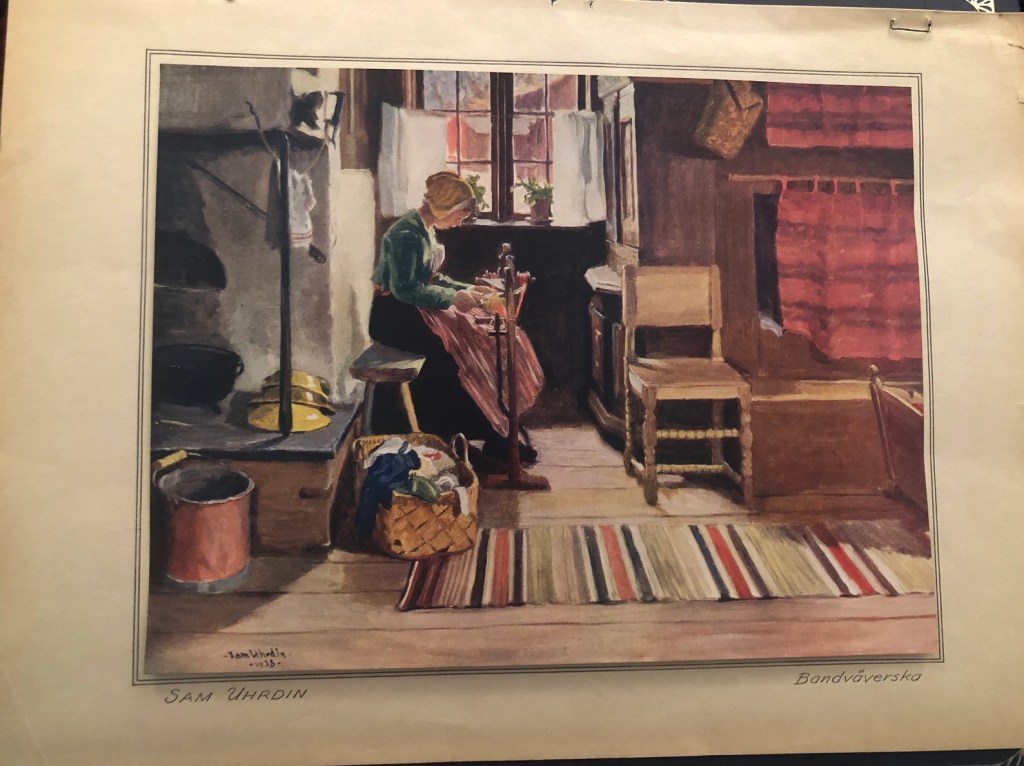

For those on Facebook, Kirsi started a “Leksand Loom” group, in which she has shared some lovely artwork, including from local painter, Sam Uhrdin (1886-1964), depicting women weaving at their band looms.

Photos of Kirsi’s looms, and much more, can be found in Kirsi’s excellent article on Leksand looms in the Spinning Wheel Sleuth’s Handloom Supplement #23.

Given that these looms were only made in Leksand, it is not surprising that they seldom turn up anywhere but Sweden. There are only a handful of which I am aware in the United States, so I am incredibly fortunate to have one (thank you Florence).

My loom was featured in The Spinning Wheel Sleuth’s Handloom Supplement #4. The article’s author, Marion Satchwell, found the loom at an antique show in Florida in the 1990s.

It came with a wee bit of black and white woven tape, which was passed on with the loom. That tape was made with what looks like fine sewing thread for the background and silk pattern threads.

The Leksand looms were made by local carpenters and ranged from simple to ornate. The carpenter who made mine was skilled and made the loom as lovely as it is functional.

The colorful paint has faded, but continues to highlight the loom’s turnings and design.

I especially love the upright between the ratcheted spools, with reminds me of a woman with arms that lower and raise to keep the spools properly in place.

The leashes for attaching the warp ends are secured through holes in the spools.

The treadle is attached to the rigid heddle by a curved piece of wood provided by a perfectly imperfect sapling in a Swedish wood, bent by some force of nature, now living on in a Leksand loom.

It is hinged to the treadle and has a slit at the top for the rigid heddle.

A lower bar holds the half heddles and the corrugated top bar keeps the upper warp threads spread out, making for easier shed changes.

The frame has a convenient carved-out storage box, full of bobbins,

with a rotating lid with letters, probably “NA,” scratched on top.

Whoever NA was, she did a lot of weaving,

because there is heavy wear on the lower cross bar and treadle—with a deep hollow made by a smallish shoe heel on the treadle.

How I wish she could have transmitted some of her knowledge to me. Because it was a real challenge to figure out how to best set up and use this loom.

There are no manuals for weaving on Leksand looms and I did not know Kirsi then. After months of research, head scratching, messages to and from people who might be able to help, experimentation, and good dose of serendipity—I went from confused to enamored.

My first stroke of luck came right after I brought the loom home when a Swedish band knife came up for sale on eBay.

About a month later, another three came up for sale together and no one bid on them (but me, eventually).

Since then, I have only run across one other for sale, so I was extremely lucky to find these right after I got the loom. Apparently, many of the knives of this style were made in Mora, Sweden, often with dates and initials inscribed on the blades. Each of mine is different, perhaps giving the weaver some choice in size and weight—a particular balance and heft.

But all were designed for hours of weaving—comfortable in the hand, smooth, and nicely weighted, so that a weaver can continuously pick, slide, and whack/whack almost effortlessly. They feel amazing—the wooden handles and brass blades are incredibly smooth—I love to run my hands over them. The oldest has deep grooves in the blade from angling and lifting the shed to transfer the bobbin.

Using them gives me a feeling of intimate connection with their previous owners, knowing we have shared a common experience—the specific fit and feel of the wood in the hand, the certain way the blade tip picks up the threads, the smooth slide and angling of the shed, the force of the beat—unique to each knife.

They are marvelous tools. For more about them, Lois Swales wrote an article in the Spinning Wheel Sleuth Handloom Supplement #16. As a bonus, her article includes a photo of one of Louise’s looms, which appears to be a twin to mine–so likely by the same maker. According to Louise, that loom had been imported from Sweden by a California decorator for use as a bathroom towel rack. Such an indignity! Fortunately, it survived and is weaving again.

Louise’s loom, like mine, had lost its original rigid heddle. Not surprising, because they are quite delicate and easily broken or lost—in fact, it is rare to find one with an intact heddle. My loom had a new heddle when I got it. It was nicely made, but only big enough for 29 pattern threads, and it wobbled from side to side. Since many of the traditional Leksand bands used 33 pattern threads, I wanted to find someone who could make me one close to the originals. Not an easy task. While researching possibilities, what should appear on eBay but an antique Leksand rigid heddle?

I was gobsmacked—they NEVER come up for sale. More loom serendipity. Because, when it arrived, it fit into the treadle bar slot as if made for it and the two holes in the inserted portion lined up exactly with the holes in the treadle bar.

At the time, I ignorantly did not think much of that, assuming that there must have been a certain uniformity in the rigid heddles make in Leksand. Ha. Since then, all of the Leksand rigid heddles that I have seen have been different—nothing uniform about them.

Which makes me think that I may have lucked into a rigid heddle made by the maker of my loom. How weird would that be?

I am not an experienced or particularly proficient band weaver, but with this loom and antique heddle, I can easily weave the complicated 33 pattern bands found in Leksand. I do not know if the way I weave is historically accurate, but no matter. It is fun, rhythmic, very tactile, and satisfying. This loom is a rare link to a very specific time and place that I am fortunate to be able to enjoy. Thank you to everyone in Leksand and beyond who saved these looms, especially those who had no idea what the looms were, but appreciated their unique beauty.

For more information on these looms:

Foulkes, Susan J., Weaving Patterned Bands, Schiffer Publishing, Ltd., Altglen, PA 2018, pp. 13-16.

Manni, Kirsi, “Band Looms from Leksand, Sweden,” The Spinning Wheel Sleuth Handloom Supplement, Issue 23, June 2022, 2-4

Satchwell, Marion, “A Swedish Ribbon Loom,” The Spinning Wheel Sleuth Handloom Supplement, Issue 4, April 2001, p. 12.

Swales, Lois, “Band-Loom Weaving Tools,” The Spinning Wheel Sleuth Handloom Supplement, Issue 16, June 2014, pp. 6-8.

Thanks to Susan Foulke’s blog, “The Durham Weaver,” for many of the manuscript pictures and to Kirsi Manni for the artwork from Leksand.